Designing the production process and layout describes how a factory produces products and machines are positioned. It includes identifying the production processes, diagrams and machinery layout. Production process and layout provide details on steps required to transform raw materials into semi-finished and finished goods, and machinery layout identifies the most economical and technical arrangement of machinery within a production facility that will maximize production efficiency and productivity, along with worker safety and comfort. These processes can include things like raw materials inspection and load, assembly, fabrication, grinding, blending, finished products, testing, packaging, and shipping.

Both production processes and machinery layout are important for several reasons. First, efficient and effective production processes are essential for meeting customer demand while minimizing costs and maximizing profits. By optimizing production processes, companies can reduce waste, minimize downtime, and improve quality, ultimately resulting in higher levels of customer satisfaction and greater profitability.

Similarly, a well-designed machinery layout can help improve efficiency, reduce the risk of accidents or injuries, and create a more comfortable and productive work environment for employees. By optimizing the placement of machinery and equipment, companies can minimize the distance workers need to travel, reduce the risk of collisions or other accidents, and create a more ergonomic workspace.

Step-By-Step Process

- Define the production requirements as explained in the previous article. This action includes understanding the product’s purpose, function, features, and any specific requirements or constraints. The best document to obtain such information is the production program.

- Obtain details on the production process and layout from selected production technology.

- Map the production processes to transform raw materials into finished products. This process involves identifying the optimal flow of materials and information, eliminating inefficiencies and bottlenecks, and designing a process that is both efficient and effective.

- Draw a diagram illustrating the production processes.

- Evaluate machinery layout options and choose the best machinery arrangement that can support production efficiency and productivity. This activity involves determining the optimal placement of each machine based on the flow of materials and products through the production line, as well as any other considerations, such as safety, accessibility, and maintenance requirements.

- Prepare the document as per the above outcomes, and share it with your team and experts.

Example

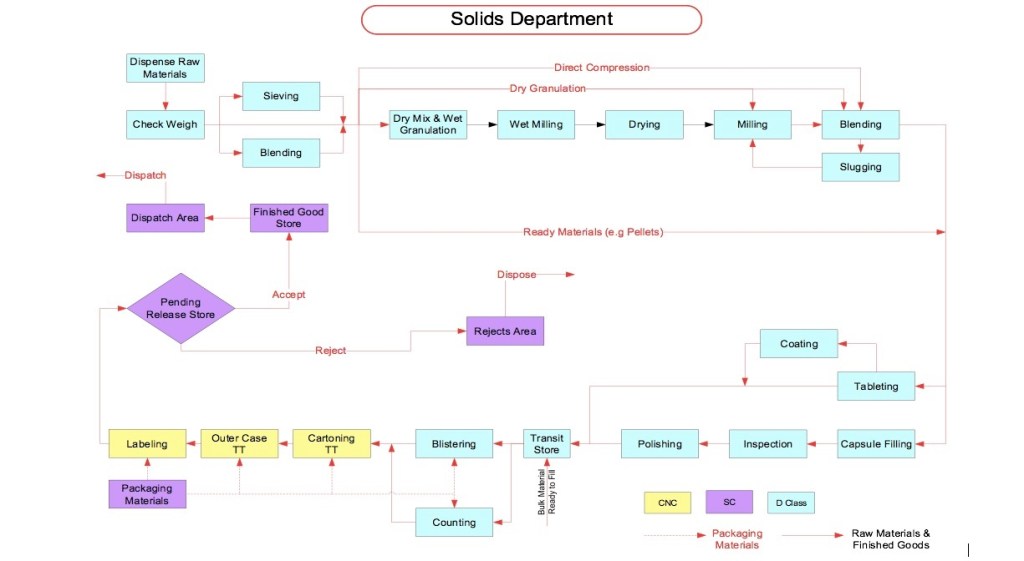

Here is the production diagram for a pharmaceutical manufacturing facility:

Useful Tips

- Define your manufacturing products and check the production technology.

- Document the production processes to be simple and easy to implement.

- Choose the processes and layout that can maximize production efficiency and productivity.

- Standardize processes to ensure consistency and efficiency in production.

- Consult experts and share discussions with your team and stakeholders.

Things To Avoid

- Not documenting the production processes.

- Relay on assumptions instead of facts and data.

- Not considering the impact of external factors such as suppliers or customers.

Final Note

This article is sourced from my new book- Your Guide For Preparing An Industrial Feasibility Study.

For more information about the book: https://growenterprise.co.uk/book-your-guide-for-preparing-an-industrial-feasibility-study/

To register in our newsletter: http://eepurl.com/ggcC29

Or email us at: maldawood@growenterprise.co.uk

The author: Munther Al Dawood- Industrial Enterprise Expert